Special Steel

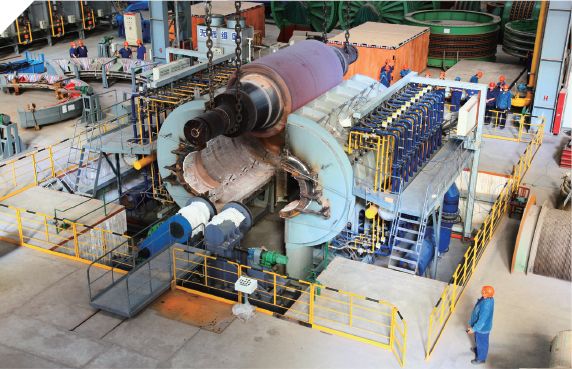

CITIC Pacific Special Steel is the largest dedicated manufacturer of special steel in China with an annual production capacity of 9 million tonnes.

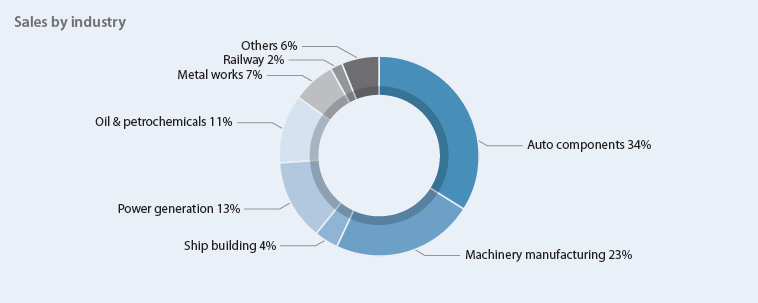

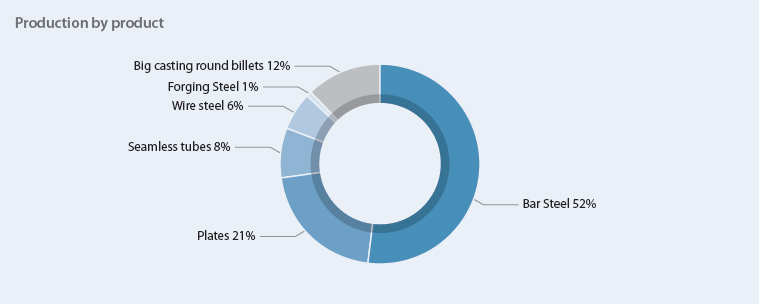

Major products include bars, plates, seamless steel tubes, wires, forging steel and big casting round billets. These products are widely used in the bearing, auto components, energy, machinery manufacturing, oil and petrochemicals, transportation, shipbuilding and other industrial sectors.

CITIC Pacific Special Steel’s operational approach is based on setting production volumes in accordance with customer orders. This allows it to keep production and sales volumes in balance with minimum inventory.

Year in review

In 2014, CITIC Pacific Special Steel sold a total of 7.4 million tonnes of special steel products, a 2% increase over the previous year. This increase came mainly from plate and wire products. Although the average selling price decreased slightly, this was accompanied by a significant fall in the price of raw materials, in particular iron ore and coking coal. As a result, the profit margin improved. Profit rose 28% from 2013 to HK$1.66 billion. Export volume registered a 22% increase, accounting for 18% of total sales.

In 2014, the company extended its cooperation with Caterpillar, Siemens, Sumitomo Corporation and other clients. The company’s strategic relationships with well-known domestic and overseas companies such as SKF of Sweden, China State Construction Group and China Railway Group provide CITIC Pacific Special Steel with a solid foundation for expanding sales across major markets.

Looking forward, the steel industry will continue to face the challenges of overcapacity and stringent environmental regulations. To control operating costs, the company will focus on the development of new products and the upgrade of energy-saving and environmental protection facilities.

|

|

|

Products

Of the total 7.4 million tonnes of products sold in 2014, bar steel represented half of the sales volume. There were also more plate products sold as a result of extensive marketing efforts. Moreover, there was a sharp increase in wire steel production in 2014, due to the completion of a new wire production facility at the end of 2013.

Innovation is fundamental to remaining competitive, and part of the company’s strategy is to develop new products to replace 10% of its existing product line-up each year. During 2014, CITIC Pacific Special Steel continued to focus on the introduction of new plate and wire products to enhance its overall product mix. New products totalled 1,040,000 tonnes, about 14% of the year’s production.

CITIC Pacific Special Steel’s technical centres, laboratories and post-doctoral research centres have been tasked with developing new products as well as offering consultation services to clients on special steel applications. For the new products to be recognised and accepted by the market, it is necessary that they are certified by customers and relevant agencies. One of the challenges in the year ahead will be to speed up the stringent and time-consuming certification process. In addition, the focus will continue to be on improving production management, operational efficiency and quality control with the goal of maintaining the company’s leading position in the domestic market and expanding its overseas exposure.

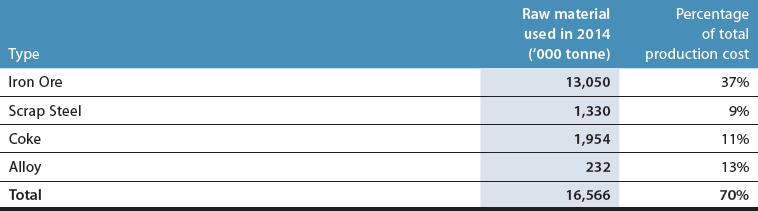

Raw materials

Having a secure and sufficient supply of raw materials is vital to the success of the business. As these raw materials account for around 70% of plant production costs, it is critical that costs are kept as low as possible.

Customers

In 2014, 76% of products were sold directly to customers rather than through distributors. Selling directly to customers gives steel plants greater visibility and stability in terms of volume requirements and pricing structures

China accounted for 82% of CITIC Pacific Special Steel’s sales in 2014. Other key markets included Korea, South East Asia, Europe and North America.

Many buyers are producers affiliated with, or contracted to, manufacturers in the auto, machinery and oil and petrochemical industries. They include end users such as Nissan, Audi, Ford, Toyota, General Motors, Honda, Volkswagen, Caterpillar and Michelin.