Manufacturing

CITIC Dicastal

CITIC Dicastal (“Dicastal”) is the world’s largest producer and exporter of automotive aluminium wheels. The company also manufactures a full range of lightweight aluminium cast components for automotive powertrain, chassis and body systems under KSM Castings. With engineering, research and manufacturing teams across the globe, Dicastal focuses today on accelerating the development of the lightweight components and integrated processes that will drive the future of transportation in automotive and beyond.

A wholly-owned subsidiary of CITIC Limited, Dicastal is headquartered in Qinhuangdao, Hebei Province of Northern China. The company has 21 facilities across China, North America and Europe and employs more than 6,400 staff around the world. Total annual production capacity is 48 million aluminium wheels and 97,800 tonnes of aluminium castings.

Year in review

In 2016, growth remained decent in the Chinese automotive sector. Total automobile production volume was estimated at approximately 28 million vehicles, representing an increase of 13.7% over 2015. Demand in the US and Europe, however, picked up only gradually.

Throughout the year, Dicastal achieved increasing margins in premium product sales and greater overall economies of scale as a result of its ongoing investment in new production technologies. Outperforming the market, the company increased its total sales by 21.6% to RMB19.7 billion. Net profit was recorded at RMB875 million, up 20.7% over 2015. In 2016, Dicastal sold 45.7 million units of wheels, a 21.7% increase over 2015. Castings sales recovered, growing 6.6% to reach approximately 74,000 tonnes.

During the year, construction of several new production facilities, expanding the company’s overall production capacity to catch up with growing demand.

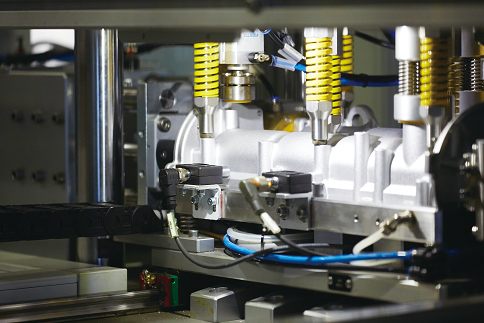

In the US, Dicastal’s new wheel plant in Michigan entered trial operation in early 2016, completing its first bulk dispatch in late May. The facility has a designed annual capacity of 3 million wheels. In China, as domestic demand for high quality aluminium cast components continued to rise, the company began trial production in January 2017 at its KSM (Chengdu) Phase I plant. This facility has a designed annual capacity of 20,000 tonnes. After the full commissioning of Phase I, construction of Phase II will follow, which will add another 20,000 tonnes of capacity upon completion. The company also upgraded its Wuxi manufacturing base to increase production capacity by 2.6 million wheels per year. All of the new facilities are equipped with advanced robotics and smart production systems.

At the headquarters, it completed the installation of new proprietary testing equipment, established a dedicated mould development centre and launched an innovation taskforce.

Dicastal’s new testing facility has set an industry benchmark for crash and stress tests. Unlike traditional road test facilities, it is capable of conducting fully simulated in-house wheel and chassis tests, thereby minimising safety concerns.

Expanding Dicastal’s capacity to directly produce a greater range of products on site, the new mould centre has an annual capacity of 2,300 sets.

A long-term investment in research and development, Dicastal’s new innovation taskforce has the mandate of creating a long-standing technological advantage over its peers. The taskforce has a wide range of sophisticated modelling and processing tools at its disposal, including digital sludge systems, 3D printers and virtual reality machines, to help it improve existing services and explore new technologies. The team’s priority is to extend Dicastal’s offering in synchronous design services to include the exterior design of wheels, a function previously fulfilled by clients.

Customers

Major customers for Dicastal’s aluminium wheels include the 12 leading global automakers, as well as 6 Chinese automakers. Dicastal is also a global strategic partner of various leading automotive companies.

Major customers for lightweight aluminium cast components include Daimler and Volkswagen and parts manufacturers such as TRW, ZF and Bosch.

In 2016, Dicastal’s top 10 customers accounted for over 39% of total sales.

In July 2016, the company has formed a strategic alliance with Williams, one of the world’s leading Formula One teams in Oxford, for motor racing and advanced engineering.