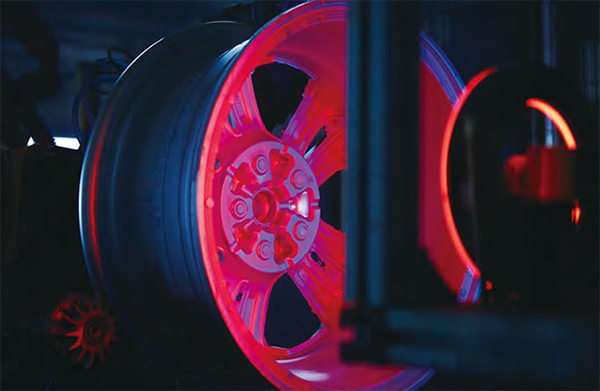

Unlocking Dicastal Intelligence: The Breakthrough Moment

Mr Huang Xiaobing, Chief Information Officer

Dicastal Intelligence is a research platform that applies laser bonding, data-matrix (DM) coding and Internet of Things (IoT) to enable largescale data collection and analytics.

Immediately after a component is moulded, we assign it a unique ID and laser it with a DM code before it continues to production. Each ID marks the entire life and journey of Dicastal products — from their formation and distribution to final assembly in all types of cars around the world.

During the production stage, sensors integrated directly into our manufacturing lines collect real-time data on every minute variance of each component. This data is then tagged to their QR code and routed to a centralised digital management system (DMS).

By now you must be thinking: ‘How is this a big deal?’

With an ID, we can quickly access targeted data on each component. This unlocks two major new channels of information. Operationally, our customers benefit from access to full traceability of each component. It also enables fast analysis and error identification during assembly and, if needed, automatic filtering and removal of the faulty parts.

Dicastal, on the other hand, is leveraging big data analytics to mine all this data so we can develop smarter production methods that eliminate more inefficiencies, improve product quality and better automate troubleshooting.

So why is no one else doing this?

For starters, you can’t just stamp things onto aluminium. If you tried that, the extreme changes in temperature, pressure and all variety of finishing techniques would simply render the stamp useless. Laser bonding gets you around the heat and pressure changes.

But finishing presents other challenges, so we had to find just the right spot for each code. We’ve spent years developing the models we now use to precisely place codes in unique locations on each product design. We have also derived a specific way to collect data in real time without compromising efficiency on our existing production lines. Already, Dicastal Intelligence is integrated into a third of our global production capacity for aluminium wheels.

Breakthroughs like Dicastal Intelligence are helping to advance the broader revolution in smart production taking place today all around the world. This is a story we share, and at Dicastal, our commitment is always to keep bringing that future closer, one wheel at a time.