CITIC Dicastal

CITIC Dicastal is the world’s largest producer and exporter of automotive aluminium wheels. It also produces automotive lightweight aluminium castings, including chassis parts, power train parts and body parts.

The company currently has 21 manufacturing bases, of which seven are outside China. Total annual production capacity is 43 million aluminium wheels and approximately 70,000 tonnes of aluminium castings.

Year in review

The automotive sector experienced varying growth throughout the year. Conditions became soft in China, with the volume of automotive production in China estimated at approximately 24.5 million vehicles, representing an increase of approximately 3.3% as compared to 2014. On the other hand, demand increased significantly in markets such as the United States and Europe.

CITIC Dicastal sold 37.54 million aluminium wheels in 2015, representing a 9% increase over last year. Sales of aluminium castings, however, decreased 5% from 2014 to 69,000 tonnes due to a key customer suffering significantly lower sales.

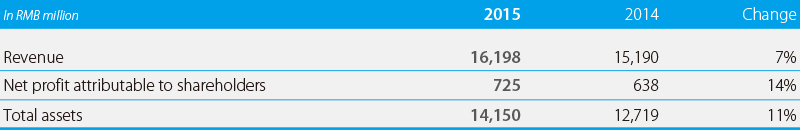

For the year 2015, the company recorded revenue of RMB16.2 billion, growing 7% over the previous year. The increase was driven primarily by the increase in aluminium wheel sales. Aluminium wheels accounted for the majority of revenue at 71% of this year’s total. International revenue contributed 51% of total revenue in 2015.

With improved manufacturing technology, production cost was reduced. As a result, net profit attributable to shareholders in 2014 increased to RMB725 million, up by 14% over 2014.

CITIC Dicastal continued to improve distribution and grow production capacity throughout the year. Construction of its aluminium wheel plant in Michigan, USA progressed on schedule. Built to enhance CITIC Dicastal service to customers in North America, it is expected to enter operation in 2016. The plant will have an annual production capacity of 3 million wheels.

Construction also began on a new integrated facility to make moulds for both aluminium castings and wheels, designed to enhance production quality across both product lines, it will become operational in early 2017.