CITIC Dicastal

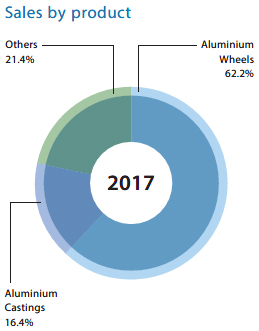

CITIC Dicastal is the world’s largest producer and exporter of automotive aluminium wheels. The company also manufactures a full range of lightweight aluminium cast components for automotive powertrain, chassis and body systems under KSM Castings. With engineering, research and manufacturing teams across the globe, CITIC Dicastal today focuses on accelerating the development of the lightweight components and integrated processes that will drive the future of transportation in automotive and beyond.

A wholly-owned subsidiary of CITIC Limited, CITIC Dicastal is headquartered in Qinhuangdao, Hebei Province of Northern China, with 24 facilities across China, North America and Europe. Total annual production capacity is 57.7 million aluminium wheels and 108,700 tonnes of aluminium castings.

Year in review

In 2017, the Chinese automotive sector experienced moderate growth. Total automobile production volume reached 29.02 million automobiles, representing an increase of 3% over 2016. As the industry worldwide continue to recover, demand from the US and European markets also registered stable development.

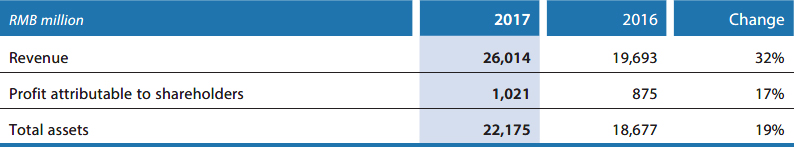

Throughout the year, CITIC Dicastal focused on aggressively expanding its market share and sold 51.28 million wheels, a 12% increase over 2016. Castings sales grew 4% to reach approximately 77,100 tonnes. The surge in wheel and castings sales drove up total revenue to RMB26 billion, a rise of 32% over last year. The company’s sustained focus on adopting intelligent manufacturing innovations and continuing efforts to lower production costs, pushed net profit up to RMB1 billion, 17% higher than last year.

Catering to rising domestic and overseas demand, CITIC Dicastal continued to invest in capacity expansion in 2017.

The company’s latest capacity investment is currently under development at its headquarter Qinhuangdao production facility, where CITIC Dicastal commenced construction last year of its sixth production line. Featuring advanced robotics and smart production systems, it has a designed annual production capacity of three million wheels. Construction is scheduled to be completed within the first half of 2018, when this facility will significantly advance the company’s core competency in wheel manufacturing.

Throughout its network, CITIC Dicastal also reached key milestones in capacity expansion. The company’s Michigan wheel plant produced 1.5 million wheels in 2017, progressing rapidly towards fulfilling its designed annual production capacity of 3 million. The Wuxi manufacturing base, with a designed capacity of 2.4 million wheels per year, has now also entered commercial production. Development of KSM’s new manufacturing facility in Chengdu, meanwhile, advanced on schedule, adding new annual production capacity of 6,000 tonnes of aluminium castings. By the end of 2018, this number will reach 11,000 tonnes.

Customers

Major customers for CITIC Dicastal’s aluminium wheels include the twelve leading global automakers, as well as the six major Chinese automakers. CITIC Dicastal is also a global strategic partner of several top automotive brands.

Major customers for lightweight aluminium cast components include Daimler and Volkswagen and parts manufacturers such as TRW, ZF and Bosch.

In 2017, CITIC Dicastal’s top ten customers accounted for over 32.8% of total sales.

Research and development

CITIC Dicastal is a leading innovator in wheel and castings design and manufacturing. Among its cutting-edge production technologies, it maintains an automated system for product design and modelling that reduces standard processing time by 20%. Its proprietary smart production systems embedded in 70% of its equipment and facilities also optimise overall manufacturing efficiency. At its CITIC Dicastal Engineering Technology Institute, the company additionally researches integrated solutions for aluminium wheels and cast components design and manufacturing.

Beyond technology, the company has also advanced materials research. CITIC Dicastal has successfully developed new aluminium and magnesium alloys. With superior strength and durability over conventional alloys, this new material has broad applicability in manufacturing lightweight automotive wheels and components.